The effluent from the Electroplating Industries is generally low in solids content and contains metals like chromium and manganese in the effluent.

The effluent from the Electroplating Industries is generally low in solids content and contains metals like chromium and manganese in the effluent.

The effluent is preheated and then fed to the Multiple Effect Falling Film Evaporator for concentration. After concentration, the concentrate is dried using an Agitated Thin Film Dryer. This dried powder can be used as solid waste disposal or as a land fill.

The condensate obtained from the evaporator is clean and colourless liquid and it can be used back in the plant as soft water.

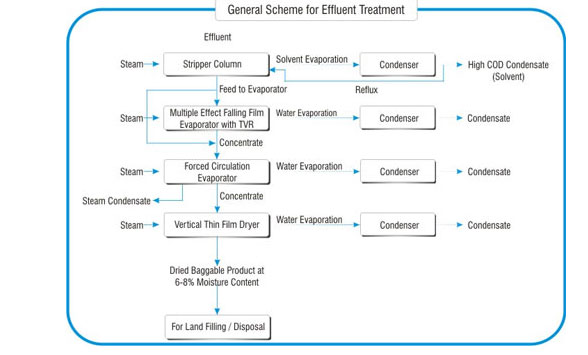

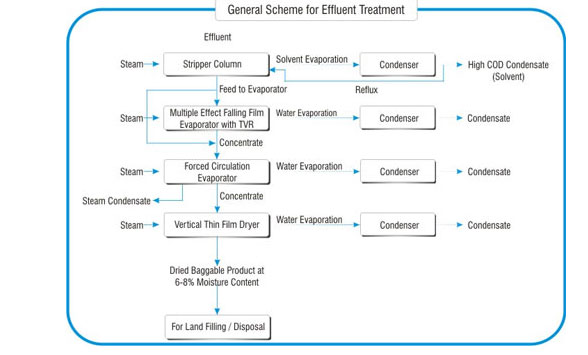

Pharmaceutical and bulk drug industries emanate effluent which consists of high organic contents with high COD. “SSP” has developed a system to treat such effluent, through evaporation & drying technology & by removing the solvent from High COD stream, using stripper column. With the help of this technology, effluent concentrate is dried to a baggable powder with 6 -8% moisture content, which can be reused as a land filling / disposal.

Pharmaceutical and bulk drug industries emanate effluent which consists of high organic contents with high COD. “SSP” has developed a system to treat such effluent, through evaporation & drying technology & by removing the solvent from High COD stream, using stripper column. With the help of this technology, effluent concentrate is dried to a baggable powder with 6 -8% moisture content, which can be reused as a land filling / disposal.

PROCESS DESCRIPTION:

For the purpose of treating this effluent, Evaporation and Drying methods are used. A combination of Industrial Evaporators like Falling Film Evaporator, Forced Circulation Evaporator and the Industrial Dryers like Vertical Thin Film Dryer are used. Other auxiliary techniques such as centrifuging, filtration, incineration are also employed depending upon the characteristics of the effluent.

The effluent containing high amount of organics is heated in a reboiler and passed through a Stripper Column to strip off the maximum low boiling organic solvents and their vapours are condensed using a condenser. These condensed vapours are partially refluxed back to the stripper to enrich the column and rest of the condensate (solvent) is collected separately and can be incinerated in an incinerator for making the facility a complete zero pollution plant.

The output liquid stream from the bottom of the Stripper Column which is now almost free of low boiling solvents enters the Multiple Effect Falling Film Evaporator /forced circulation evaporator or combination of two for further concentration. After concentration in the Evaporator, we get a concentrated stream of effluent which can be then further concentrated or dried in different types of evaporators and dryers depending upon the actual composition of the individual stream. The condensate water obtained from the Falling Film Evaporator is of very low COD. In case further reduction in COD is desired, then various techniques can be used like activated carbon treatment or aeration with a high pressure blower for prolonged periods.

Finally, whole of the effluent is converted into solid/sludge form so that it can be disposed using various ways like land filling.

SSPs strong background and its research team at the Research & Development Centre tried and tested various techniques to bring down the COD of this condensate water so that it can be used back in the industry/ discharged with COD limits well within the range as specified by the Pollution Control Boards.

KEY FEATURES

- User Friendly

- Easily Upgradable

- Low Operating Cost

- Zero Liquid Discharge

- Highest Steam Economy

- Applicable for CDM Benefit

- Less Downtime for Maintenance

- Fully Customized Designed System

- Lowest Operation & Maintenance Cost

- Generation of Reusable Condensate Water

- Conversion of liquid waste water to solid waste for TSDS facility.

- Removal of Solvent from High COD Stream using stripper column.

Electroplating Industries

Electroplating Industries The effluent from the Electroplating Industries is generally low in solids content and contains metals like chromium and manganese in the effluent.

The effluent from the Electroplating Industries is generally low in solids content and contains metals like chromium and manganese in the effluent.

Pharmaceutical and bulk drug industries emanate effluent which consists of high organic contents with high COD. “SSP” has developed a system to treat such effluent, through evaporation & drying technology & by removing the solvent from High COD stream, using stripper column. With the help of this technology, effluent concentrate is dried to a baggable powder with 6 -8% moisture content, which can be reused as a land filling / disposal.

Pharmaceutical and bulk drug industries emanate effluent which consists of high organic contents with high COD. “SSP” has developed a system to treat such effluent, through evaporation & drying technology & by removing the solvent from High COD stream, using stripper column. With the help of this technology, effluent concentrate is dried to a baggable powder with 6 -8% moisture content, which can be reused as a land filling / disposal.